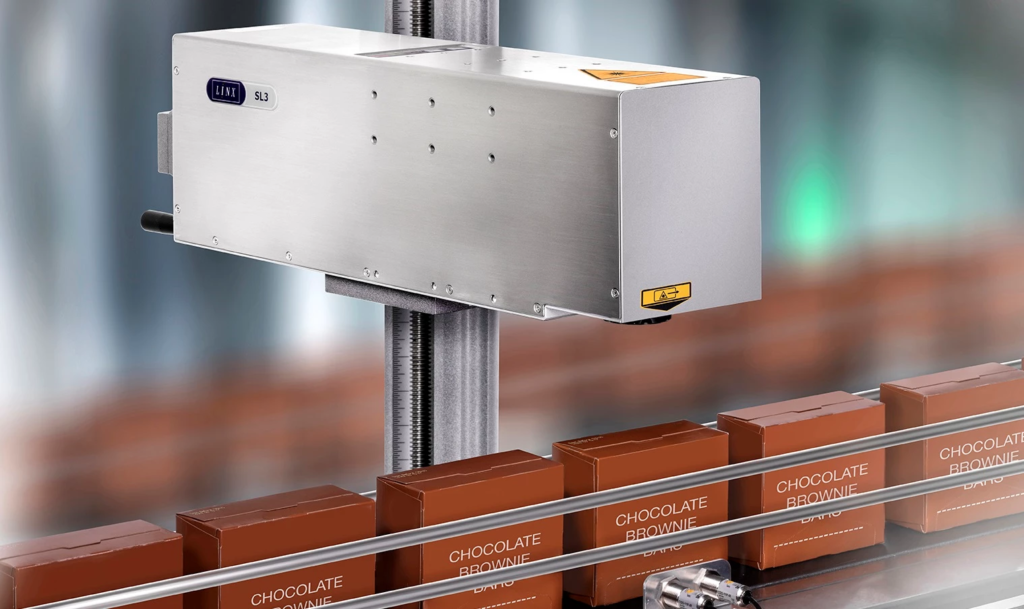

Linx SL3 Laser

30W CO2 laser coder

Robust, affordable, simple to install and operate. This 30W CO2 laatest LinxVision® Software the SL3 laser coder provides easy access operator toolbar with a range of fonts, options and operating languages.

- The laser printer machine operates without interconnections, so the risk of accidental damage to the cables by twisting or chemical reaction is eliminated

KEY BENEFITS

- Compact, complete laser marking in a single unit that meets your coding needs at an affordable price

- Operates without any consumables to minimise your running costs.

- Flexible user interface options to control your laser marking printer.

- IP54 stainless steel and anodised aluminium enclosure to withstand your manufacturing environment.

- Established and proven laser tube and marking head technology provide reliability and confidence.

- Linx laser printer operates without interconnections improving laser reliability through eliminating possibilities of interconnection failure or damage.

- Multiple mounting positions and orientations support simple and compact installations.

- Single unit installation reduces production line space usage and installation time.

- Easy and minimum maintenance increases production time and reduces running costs with the Linx laser batch code marking machine.

Printing capability

- This simple and robust, CO2 30W laser coder has the ability to code up to a maximum marking speed of 360 meters per minute, which will cover a wide range of production lines.

- With no consumable the total cost of ownership is reduced.

- The majority of materials can be effectively marked with a laser marking machine, including glass, metal, plastic and paper/card.

Programming Facilities

- Using the latest LinxVision® Software the SL3 laser coder provides easy access operator toolbar with a range of fonts, options and operating languages

- Weighing in at 21kg, the single unit integrates easily onto production lines and systems making it simple to install. The space required to house the coder, together with the installation time needed, are minimised, meaning less upheaval for already pressed production schedules. Its multiple mounting positions and orientations, together with flexible user interface options including a choice of operating languages and password protection levels, gives total control of the laser.

Physical Characteristics

- The IP54 rating of the stainless steel and anodised aluminium enclosure makes the unit secure from water splashes from any angle.

- With its two-year laser tube warranty, the Linx laser batch coder ensures optimised production output and reliability, whilst reducing total cost of ownership.

- The laser printer machine operates without interconnections, so the risk of accidental damage to the cables by twisting or chemical reaction is eliminated.

- The majority of materials can be effectively marked with a laser marking machine, including glass, metal, plastic and paper/card.